New Nolco-RIBLoad distributing protective covering for shock, impact and weather sensitive goods

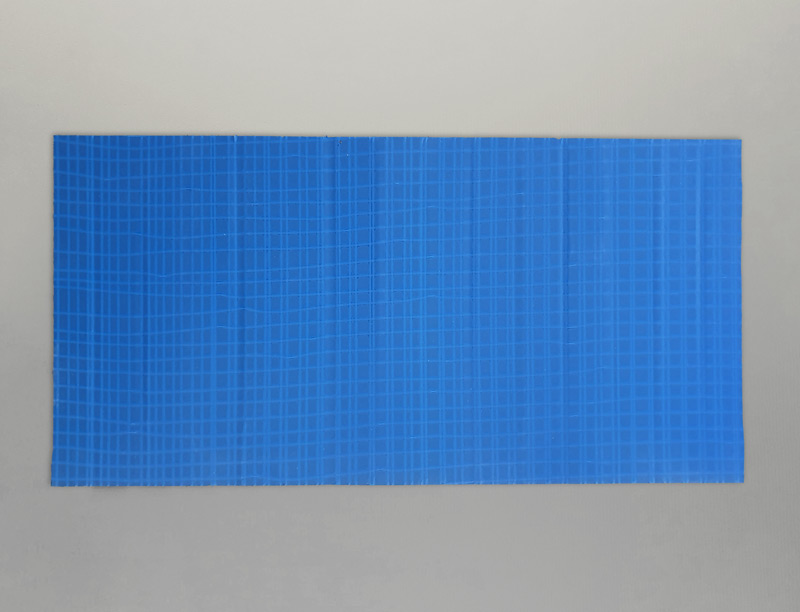

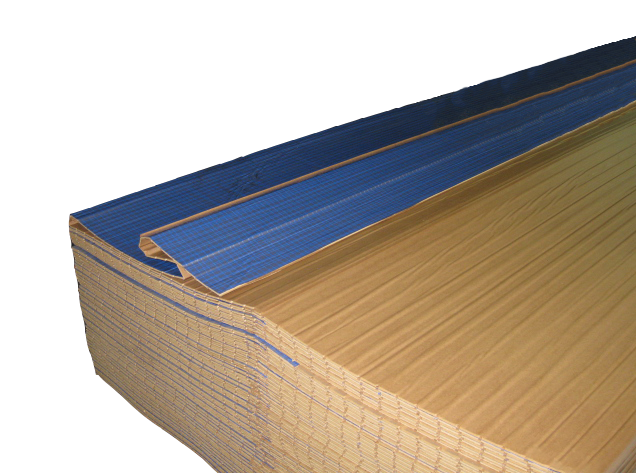

Nolco-RIB is a packaging material made of hardboard strips laminated on both sides forming a lamellar structure. As it is manufactured in running lengths of 156 m, the required length can be individually and flexibly determined in accordance with the dimensions of the packaged goods to be protected. Nolco-RIB is available in widths from 100 to 8,000 mm and therefore suitable as a homogeneous packaging material even for long products. It protects surfaces against shock and impact as well as other physical influences and is also used for the load-distributing wrapping and bundling of different objects.

Nordic Woodfibre

Why New Nolco-RIB is the World’s Best Lamella Packaging

Interlinked lamellas – means a stronger packaging!

Full coverage glue lamination – which means that the whole and each lamella is fully glued!

Interconnected sheets strongly glued – between the boards we also glue for stronger protection.

New revolutionary production methods

- reduces CO2-footprint by more than 92%

- > 98% material used are from renewable sources

- Energy 100% CO2-compensated by new tree planting

By accessing the video, you agree that third-party cookies may be stored on your computer. (Please note the privacy policy).

Product Benefits

- Easy to use

- Easy to close with simple tools

- Fast and easy one-man handling

- Protection against impact and shock effects

- Prevents scratches on the packed product due to inside lamination with kraft paper

- Surface protection against climate, oil, water and UV radiation

- Mechanical shock absorber (forklift)

- Low weight: only 2.4 Kg/m²

- No nails, staples, splinters required – no risk of damage to the packed goods

- Environment friendly – Main components made of 100 % woodfibre produced from wood residues

Saves ...

- 70 % working time (vs. wood) – you simply wrap it around your product and strap it!

- 40 % material vs. wood

- Less waste – because of cut-to-size widths

- storage – less space required

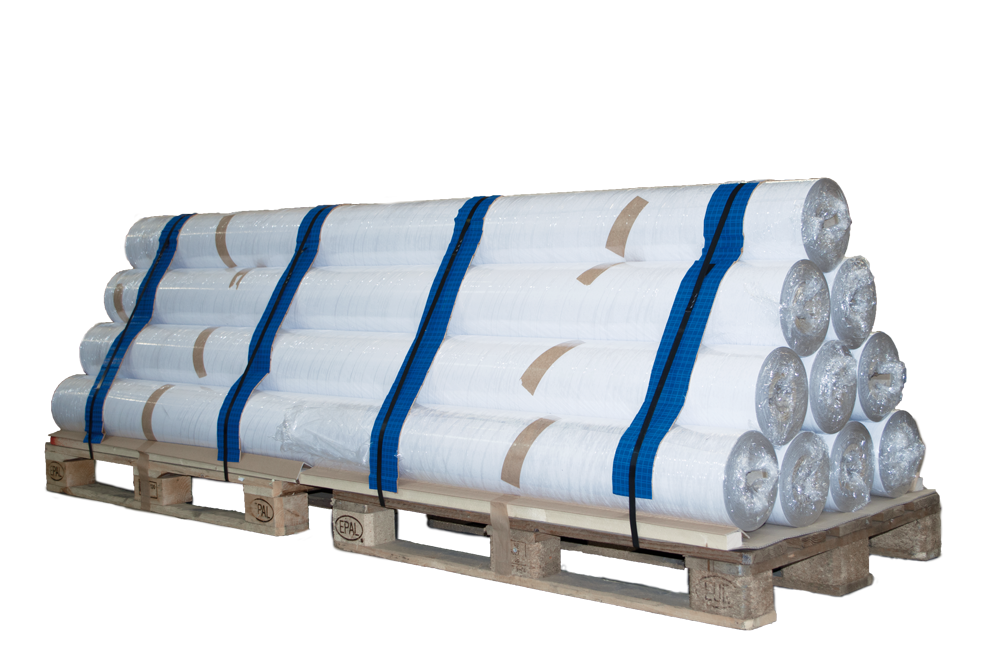

Delivery forms

- Lamella width: 30 mm

- Only 6 mm spacing

- Lamellas are only glued and the glue is heat-resistant

- Widths: 100 up to 8,000 mm

- Standard lengths: 156 m zig-zag folded or 78 m in rolls

Application

- Cover or strapping underlayer

- Coils, rollers, tubes, bars, rods, machine parts, components

![Nolco_RIB [eng] Nolco-RIB](/fileadmin/_processed_/4/1/csm_nolco_rib_english_396bed375f.png)